Product Category

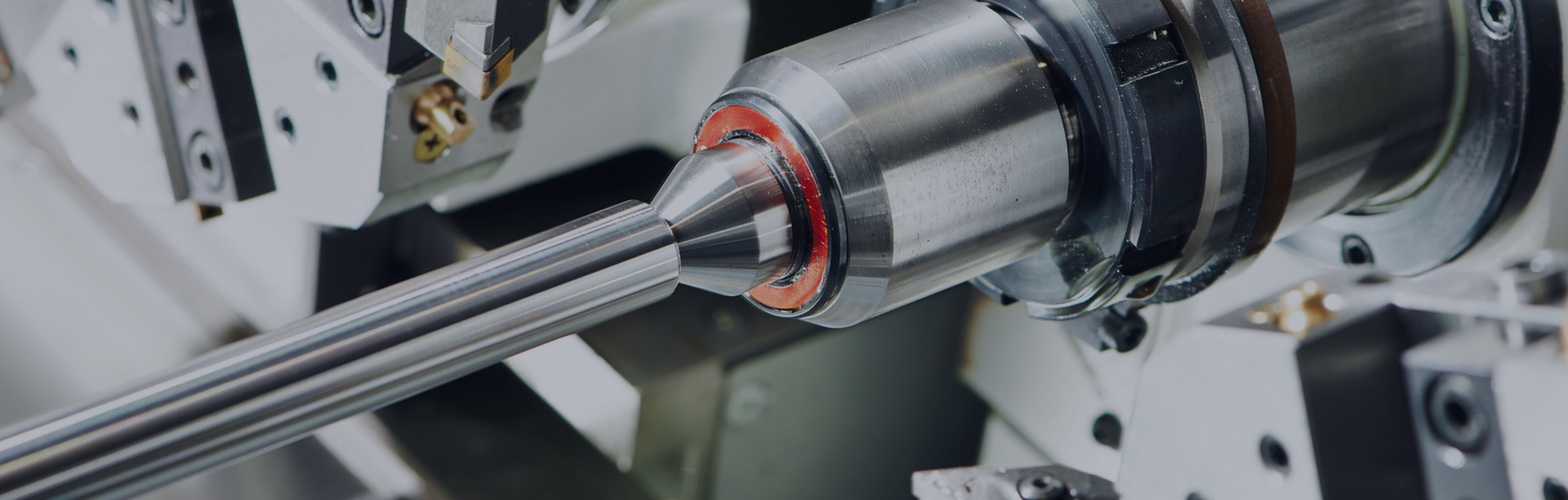

GMCX32-500 High-Speed End Face CNC External Grinding Machine

Share To:

Key words:

Product Description

Typical processed parts

Main features of the machine tool

■ Closed-loop automatic grinding work cycle

■ Zhongyuan Precision's automatic measuring instrument

■ Configured electrical cabinet

■ Automatic quantitative lubrication

■ Fully enclosed protective cover

Machine tool configuration

■ Suitable for mass production of shaft parts, grinding end faces and outer circles simultaneously in one go. Under the condition that the width of the grinding wheel is satisfied, multiple steps and end faces can be ground at once, achieving profile grinding. The more complex the shape of the part, the more the advantages of this machine tool can be reflected. Under permissible conditions, one person can operate multiple machines.

■ Uses the HNC-808DG two-axis linkage system from Wuhan Huazhong CNC Co., Ltd. (other CNC systems can also be configured according to user requirements).

■ Configured with Zhongyuan's automatic measuring instrument for online measurement, achieving a closed-loop automatic grinding work cycle to ensure processing size accuracy. Combinations can be made according to specific user requirements (other measuring instruments can also be configured according to user requirements).

■ Configured with an independent electrical cabinet (with air conditioning) and an independent oil tank.

■ The tailstock uses ball bearings for linear motion and has pneumatic retractable functions.

■ The main spindle of the headstock and the tailstock spindle use #4 Morse.

■ Configured with an automatic quantitative lubrication pump to ensure sufficient lubrication of the screw.

■ The configured protective cover is fully enclosed to ensure safe operation.

■ Configured with a larger water tank and magnetic separator or paper filter.

Grinding wheel frame

■ Grinding wheel frame feed

The feed of the grinding wheel frame and the worktable is driven by AC servo motors through ball screws, with ball screws from Taiwanese brands (other brands of ball screws can also be configured according to user requirements).

■ Guide rail

The guide rails of the grinding wheel frame and worktable use plastic-coated guide rails to improve their shock resistance and sensitivity.

■ Grinding wheel spindle

The spindle of the grinding wheel frame can use dynamic and static pressure, static pressure spindle, or direct drive electric spindle to ensure high precision of the machine tool.

Working accuracy

| Outer Roundness | Outer Cylindricity | Outer Roughness | Roughness of end face |

| 0.0015 mm | 0.005 mm | Ra≤0.4 μm | Ra≤0.8μm |

Main specifications and technical parameters

| Item | Specification | Item | Specification |

| Cylindrical diameter can be ground | φ8-φ320mm | Morse taper of spindle taper hole | 5#Mt |

| Maximum grinding length | 500mm | Head frame center height | 180mm |

| Peak height | 180mm | Drive motor | Frequency conversion motor (1.5Kw, 1500rpm) |

| Maximum allowable weight of the workpiece | 120kg | The center sleeve taper hole tailstock | 4# |

| Machine weight | 4200kg | The amount of movement of the tailstock sleeve | 30mm |

| Speed range of lead screw pair(X axis,Z axis) | 7000~0.02mm/min | pump flow | 4M/H |

| Minimum programming increment(X-axis,Z-axis) | 0.0001mm | lift | 36M |

| Maximum displacement(Z-axis) | 760mm | Roundness | 00015 mm |

| Maximum movement(X-axis) | 260mm | cylindricity | 0.005 mm |

| Size of grinding wheel | φ600xB( ≤75)xφ305 mm | Outer surface roughness | Ra≤0.4um |

| Grinding wheel linear speed | ≤45M/S |

Video display

More Products

Scan and follow

Jack Machine Tool Official WeChat

Scan and follow

Douyin official account

Support Hotline:13750639243

Address:

No.58, Juye Road, Jiaojiang District, Taizhou City, Zhejiang Province, China

No. 333, Hebu New Village, Jizhou District, Ji'an City, Jiangxi Province

Copyright© 2022 Jack machine tool co., ltd. All Rights Reserved. 赣ICP备13004481号-3

联系我们

关注我们

公众号

关注公众号

- 返回顶部

CN

CN