Product Category

MK1332 CNC External Grinding Machine

Share To:

Key words:

Product Description

Typical processed parts

Main features of the machine tool

■ Huazhong CNC 808XPG/DG two-axis linkage system

■ Mainly processes cylindrical or multi-step cylindrical parts

■ High cost performance

Machine tool configuration

■ This machine tool is a CNC external cylindrical grinding machine, suitable for batch and small batch production, mainly processing cylindrical or multi-step cylindrical parts, with high cost performance;

■ The electrical control system of the machine tool is standardly equipped with the 808XPG/DG two-axis linkage system from Wuhan Huazhong CNC Co., Ltd., using CNC servo drivers and servo motors for the execution system;

■ Simple and practical operation, can be easily operated with simple training. The operator sets the parameters for longitudinal grinding and plunge grinding through the CNC operation panel, allowing automatic processing of workpieces of different sizes. This machine tool features automatic gear shifting of the worktable, capable of automatically grinding multiple steps of a workpiece, with the sequence and grinding process parameters of longitudinal and plunge grinding arranged arbitrarily;

■ All moving parts are automatically lubricated, and the tailstock can be operated in both hydraulic and manual modes;

■ The workpiece, oil pump, and cooling pump are driven by separate motors.

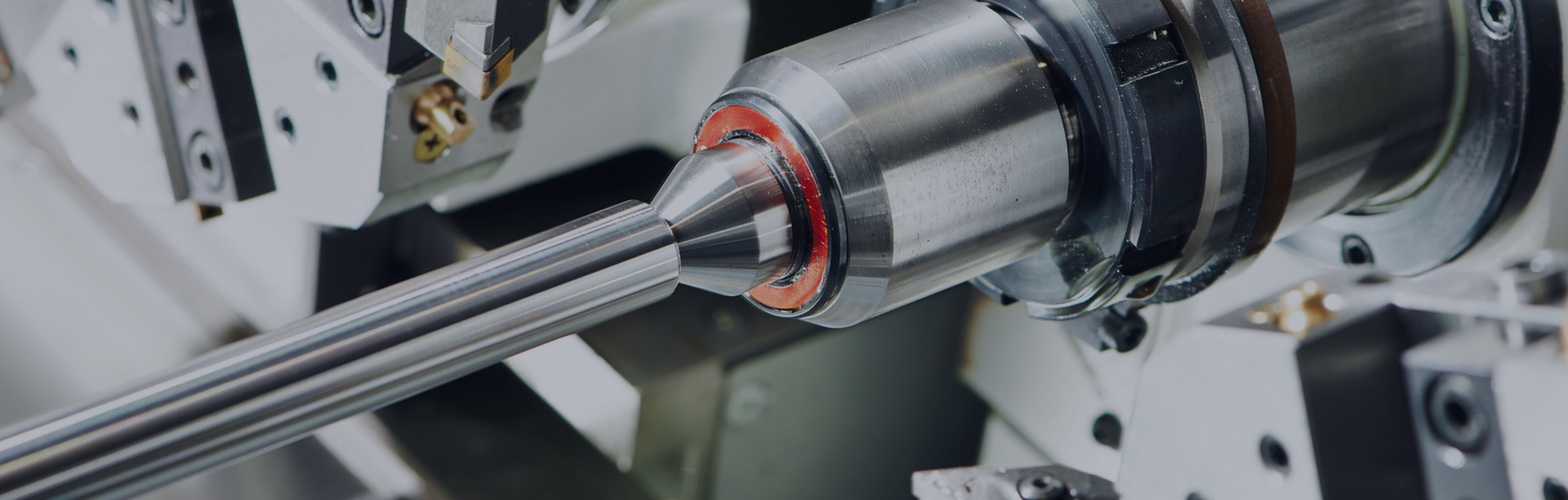

Grinding wheel holder

Has automatic grinding wheel dressing function and automatic compensation function.

■ Grinding wheel spindle

The spindle bearings of the grinding wheel holder use three-piece wedge dynamic pressure bearings or integral dynamic pressure sliding bearings, and high-precision dynamic and static pressure spindles or direct drive electric spindles can be selected according to user requirements.

■ Lateral feed

The longitudinal movement of the machine tool worktable and the lateral feed motion of the grinding wheel holder are driven by servo motors through ball screws, with high feed accuracy; equipped with an operation panel, the human-machine interface is user-friendly and easy to operate. Other systems can also be used according to user needs, and online automatic measuring instruments can be configured.

Working accuracy

| Roundness | Cylindricity | Surface roughness |

| 0.002 mm | 0.005 mm | Ra≤0.32μm |

Main specifications and technical parameters

| Item | Specification | Item | Specification |

| Maximum grinding length (outer circle) | 500/1000/1500/2000/3000mm | Maximum diameter of grinding wheel | 600mm |

| Grinding diameter range(outer circle) | φ8-φ320mm | Maximum line speed of grinding wheel | 45M/s |

| Top Center High | 180mm | Minimum feed of grinding wheel holder | 0.001mm |

| Maximum weight of machined parts | 120kg | Minimum table feed | 0.001mm |

| Tailstock sleeve movement amount | 30mm | Total machine power | 21Kw |

| Headstock spindle speed | 26-260r/min | Total weight of machine | 3500/4000/4500/6500kg |

Video display

More Products

Scan and follow

Jack Machine Tool Official WeChat

Scan and follow

Douyin official account

Support Hotline:13750639243

Address:

No.58, Juye Road, Jiaojiang District, Taizhou City, Zhejiang Province, China

No. 333, Hebu New Village, Jizhou District, Ji'an City, Jiangxi Province

Copyright© 2022 Jack machine tool co., ltd. All Rights Reserved. 赣ICP备13004481号-3

联系我们

关注我们

公众号

关注公众号

- 返回顶部

CN

CN