Product Category

MK8220 Crankshaft Follow-up CNC Eccentric Grinding Machine

Category:

Share To:

Key words:

Product Description

Typical processed parts

Main features of the machine tool

■ Standard configuration uses LYNUC CNC system

■ Fully enclosed protective cover

Machine tool configuration

■ This is a high-precision eccentric crankshaft grinding machine that can achieve grinding of single eccentric and double eccentric shaft neck outer circles, and can also grind various irregular outer circle wheels (such as cams, ellipses, polygons, etc.). High precision, high rigidity, and high efficiency are the basic characteristics of this grinding machine, which can be widely used in the aviation, medical, compressor, hydraulic, mold, and new energy automotive manufacturing industries, as well as in the grinding of camshafts, crankshafts, drive shafts, and eccentric shafts.

■ It uses the LYNUC CNC system, with 4-axis 2-linkage (grinding wheel frame feed on X-axis, sliding table movement on Z-axis, workpiece spindle on C-axis, grinding wheel spindle on S-axis, where X and C axes are linked for follow-up grinding). It adopts a new generation of user-friendly graphical programming software developed by JACK and LYNUC. It features simple and quick setup and an intuitive user interface, eliminating the need for operators to input complex G-code and subprograms, making operation simple and easy to learn, thus enhancing programming and setup efficiency, and providing a good user experience and operational feel.

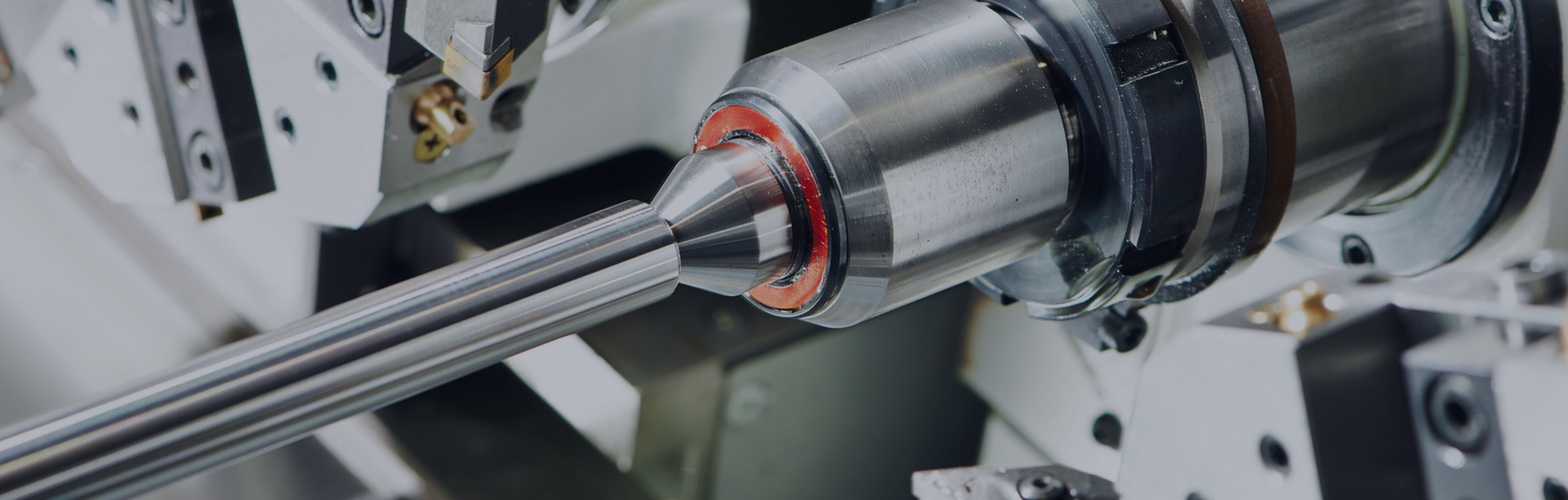

■ The headstock spindle uses a high-precision, high-rigidity electric spindle unit, equipped with British Renishaw circular grating, achieving high rotational accuracy and positioning accuracy through closed-loop control. It is equipped with Italian Marposs AE (for stroke elimination and anti-collision) device.

Grinding wheel frame

■ Grinding wheel frame feed

The grinding wheel frame feed uses a high-precision static pressure guide rail + linear motor feed system, achieving high acceleration performance at the micron level.

■ Grinding wheel spindle

The grinding wheel spindle uses a high-rigidity, high-precision electric spindle unit, achieving high-speed grinding at a speed of 6000 rpm.

Working accuracy

Working Accuracy

| Roundness | Cylindricty | Eccentricity |

| 0.002 mm | 0003 mm | 0005mm |

| Paraliclism | Outer diameter d mensional tolerance | Surtace roughness |

| 0.003mm | 0003mm | Ras0.32 um |

Main specifications and technical parameters

| Item | Specification | Item | Specification |

| Maximum length of machined parts | 300mm | Roundness of the eccentric shaft | 0.002mm |

| Range of diameters of machined eccentricshafts | 50mm | Eccentricity error of eccentric shaft | 0.005mm |

| Maximum eccentricityofthe eccentric shaft | 20mm | Eccentric shaft parallelism | f0.003mm |

| Maximum weight of machined parts | 20kg | phase angle error | 20 |

| Grinding Wheel Specifications CBN Grinding Wheel |

φ250 φ20 B( ≤40)mm | surface roughness | Rzs1.6um |

| Maximum linear speed of grinding wheel (for CBN grinding wheel) |

90m/s | Total machine power | 40Kw |

| Eccentric shaft diameter size error | 0003mm | Total weight of machine | 6000Kg |

| Sub-axis runout error relative to spindle | :0008mm | Dimensions of the main body of the machine |

1850 2150 2060mm |

| Eccentric shaft cylindricity (diameter method) | s0003mm |

Video demonstration

More Products

Scan and follow

Jack Machine Tool Official WeChat

Scan and follow

Douyin official account

Support Hotline:13750639243

Address:

No.58, Juye Road, Jiaojiang District, Taizhou City, Zhejiang Province, China

No. 333, Hebu New Village, Jizhou District, Ji'an City, Jiangxi Province

Copyright© 2022 Jack machine tool co., ltd. All Rights Reserved. 赣ICP备13004481号-3

联系我们

关注我们

公众号

关注公众号

- 返回顶部

CN

CN