Product Category

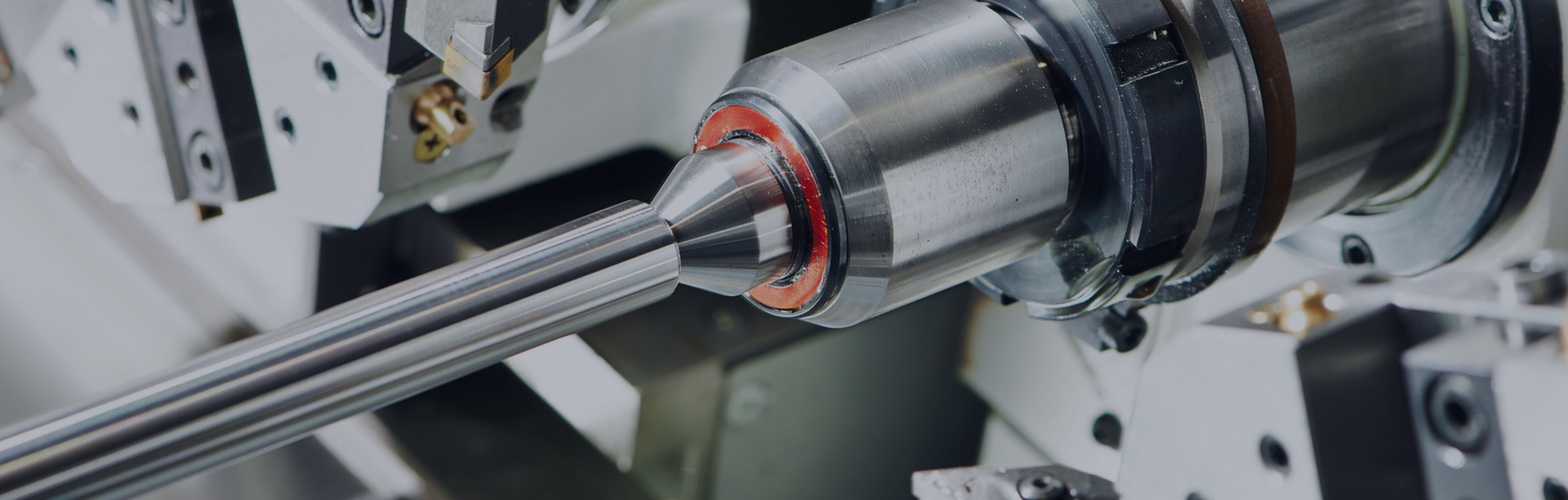

JKWG550 CNC Worm Gear Grinding Machine

Share To:

Key words:

Product Description

Typical processed parts

Main features of the machine tool

■ The grinding wheel dressing uses diamond roller CNC dressing, with high precision and good flexibility.

■ The grinding wheel motor uses an internal permanent magnet synchronous motor for direct drive, with strong power and low vibration.

■ The spiral lift angle adjustment uses servo adjustment and automatic locking, with high adjustment precision and fast speed.

■ The center hole is ground before further grinding, greatly improving the accuracy, roundness, surface finish, and dimensional accuracy of the parts.

Machine tool configuration

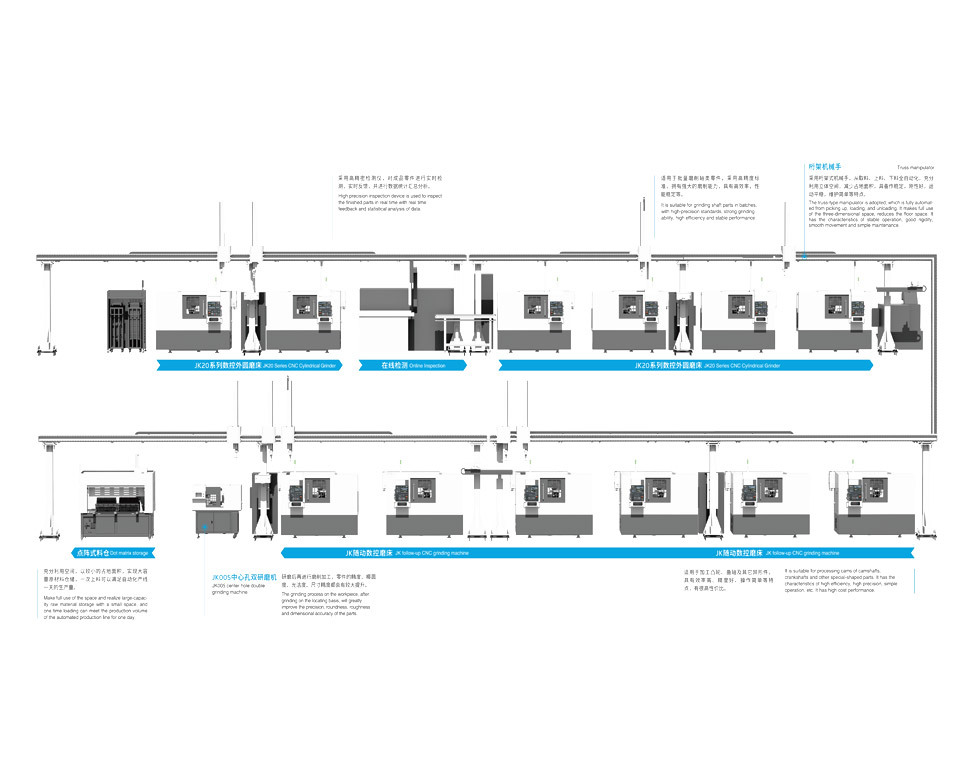

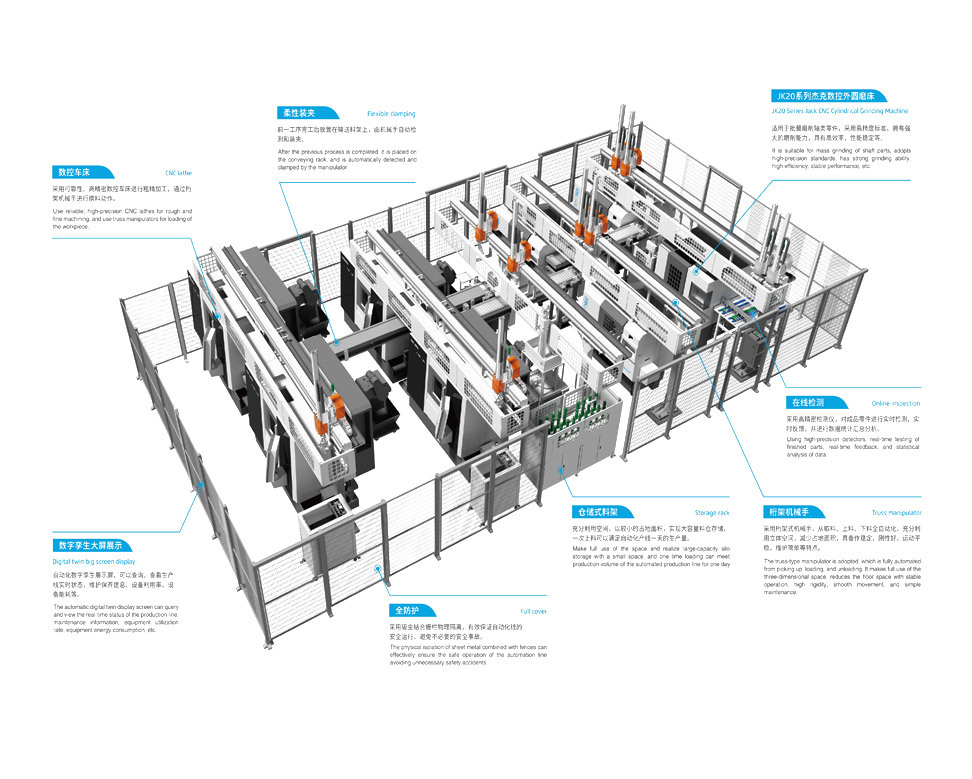

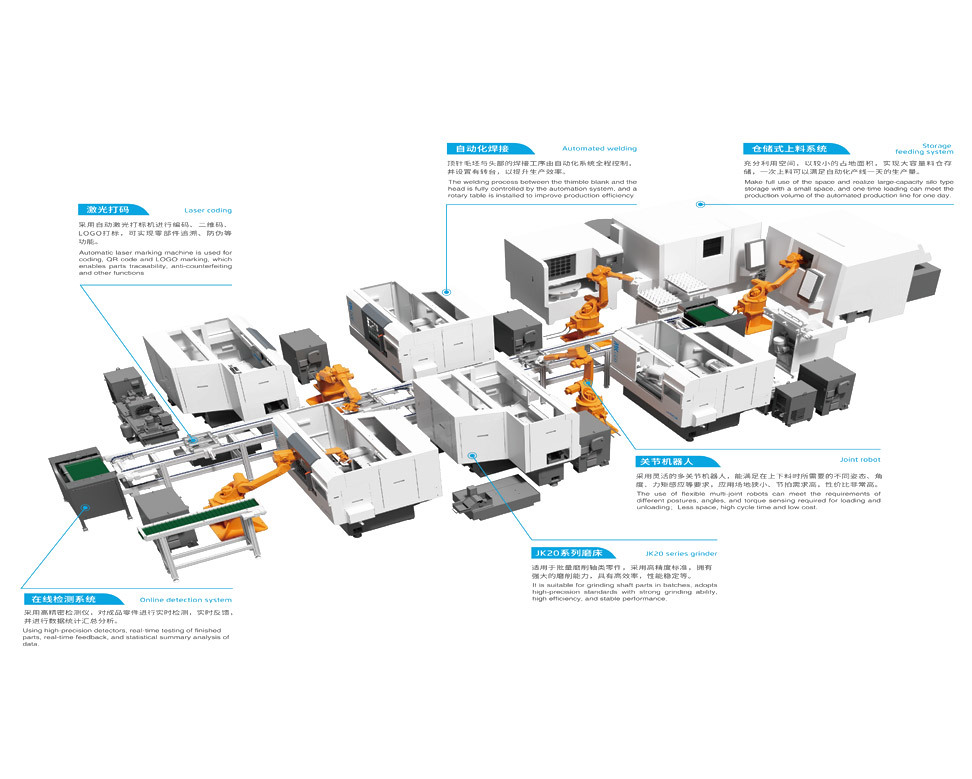

■ Mainly used for grinding various cylindrical worm gears, and can also be used for grinding various types of threaded screws.

■ Uses a CNC system to control six-axis three-linkage (Z\X\C).

Number of control axes: 6 axes

Z-axis: Longitudinal feed motion of the worktable (with grating scale, fully closed-loop control)

X-axis: Lateral feed motion of the grinding wheel frame (with grating scale, fully closed-loop control)

C-axis: Rotational motion of the workpiece spindle (with circular grating, fully closed-loop control)

A-axis: Vertical swing of the grinding wheel frame

S-axis: Rotational motion of the grinding wheel

S1-axis: Rotational motion of the roller

■ The spiral lift angle adjustment uses servo adjustment and automatic locking, with high adjustment precision and fast speed;

■ The diamond roller is driven by an electric spindle, with stable speed and low vibration;

■ The grinding wheel dynamic balancing system and online automatic tool setting device can be selected according to user needs;

■ Longitudinal (Z) and lateral (X) movements are driven by linear motors, with high motion precision;

■ Uses a fully enclosed protective cover, equipped with an oil mist extraction device, providing a good working environment and an attractive appearance.

Grinding wheel frame

■ Grinding wheel motor

The grinding wheel motor uses an internal permanent magnet synchronous motor for direct drive, with strong power and low vibration.

■ Grinding wheel dressing

The grinding wheel dressing uses diamond roller CNC dressing, with high dressing precision and good flexibility.

Working accuracy

| Accuracy achieved in grinding cylindrical worm gears | Accuracy achieved in grinding trapezoidal screws | Surface finish of the ground workpiece | |||||||||||||||||||||||||||||

| Z=1~2, level 4; z≥3, level 5 | Level 6 | Ra≤0.32 μm | |||||||||||||||||||||||||||||

Main specifications and technical parameters

| Item | Specification | Item | Specification |

| Grindable workpiece outer diameter | φ5mm-φ200mm | Grinding Wheel Specification (O.D.xID.x Thickness) |

φ400xφ203XB (B≤25) |

| Wearable worm module | M1-8 | Maximum travel (Z-axis) | 750mm |

| Range of threaded heads | 1-99 | Maximum load capacity | 25kG |

| Lead angle range | 40 | Maximum linear speed of grinding wheel | 45m/s |

| Headstock spindle speed | 0.5-45rpm | Machine dimensions (LxWxH) | 3100X2100X1850mm |

| Maximum distance between centers | 550mm | Total weight of machine | 6000KG |

Video display

More Products

Scan and follow

Jack Machine Tool Official WeChat

Scan and follow

Douyin official account

Support Hotline:13750639243

Address:

No.58, Juye Road, Jiaojiang District, Taizhou City, Zhejiang Province, China

No. 333, Hebu New Village, Jizhou District, Ji'an City, Jiangxi Province

Copyright© 2022 Jack machine tool co., ltd. All Rights Reserved. 赣ICP备13004481号-3

联系我们

关注我们

公众号

关注公众号

- 返回顶部

CN

CN